Production / Conversion products are used to create one product from several small products, such as gift baskets or multi-packs of items.

Creating a Production / Conversion Product

It is a good idea to have your products ready and set up as desired. For detailed information on creating products, please visit our creating products manual page. Make sure that Track Inventory is also selected on all products that are affected by the Production / Conversion.

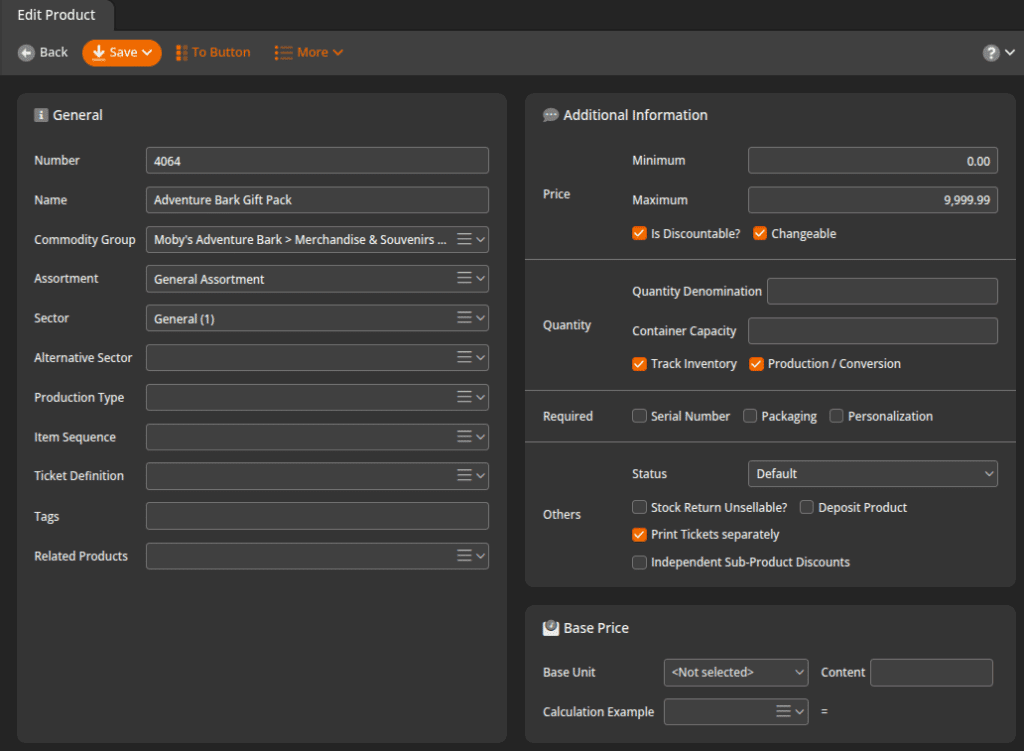

Begin by creating the product you wish to produce, filling out all the necessary and desired fields as needed.

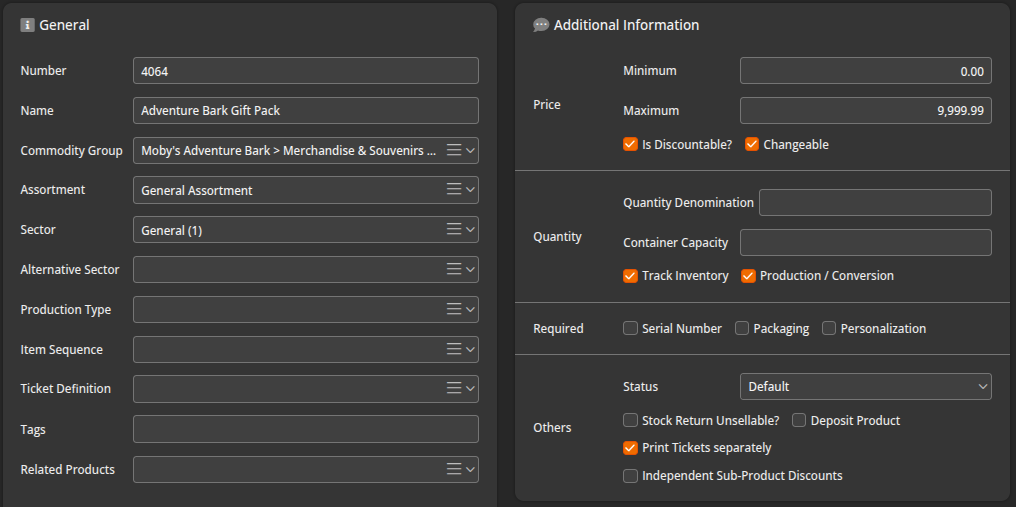

Now, go to the additional information box and tick the Production / Conversion check box.

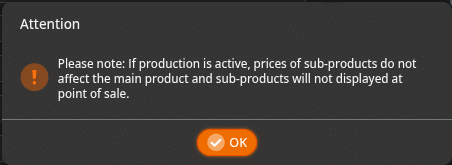

*Note: When checking this box, you will get a message saying that the prices of sub-products will not affect the main product. The sub-products will only affect the cost of producing the basket. These subproducts will not be displayed on the receipt at the POS Terminal. Click on OK to continue.

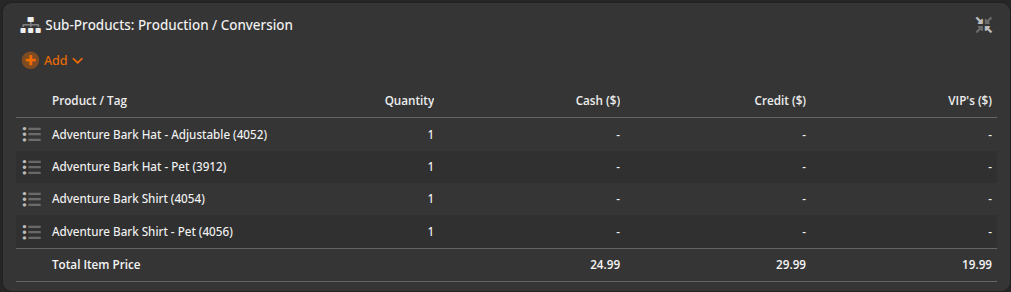

Next, go to the sub-products box on the right and add the products you wish to have converted. In this case, we are using various gift items. Notice how there is no price defined when you add the product. That is because you specify the products you wish to use to make your larger product. They will only be taken out of inventory when you run the preparation receipt function. If you do not have the production/conversion box checked as above, the products will be sold alongside your main product as if they were add-ons.

When you have everything set up, click the Save button at the top of the screen. Use the “To button” at the top of the screen to add the product to the point of sale.

For detailed information on POS Buttons & Button Configuration, please visit our Create POS Buttons / Button Configuration manual page.

Product Conversion at the POS

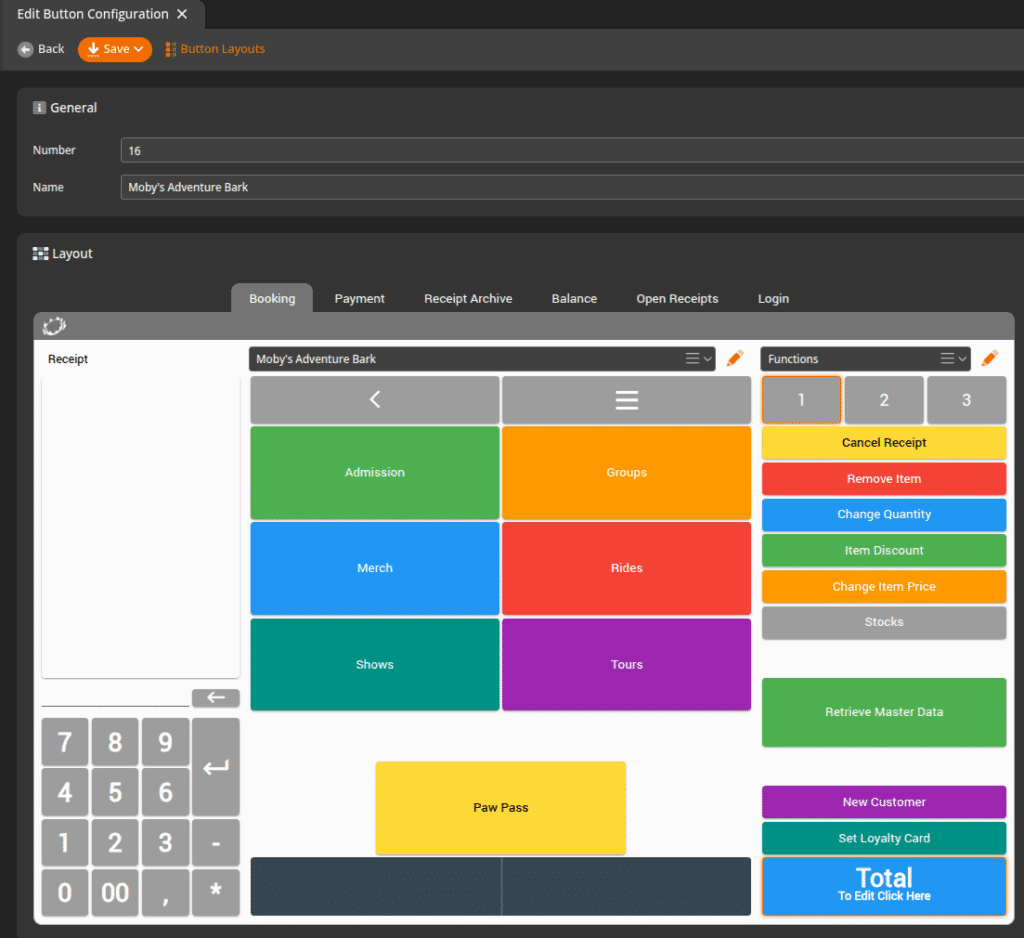

Next, create a button for the product conversion on the POS. Navigate to Settings > Button Configurations to select which button configuration to update. Select Button Layouts at the top of the screen to pick a specific button layout to add your Product Conversion button to.

*Note: Clicking the orange pencil icon will take you directly to that button layout for editing.

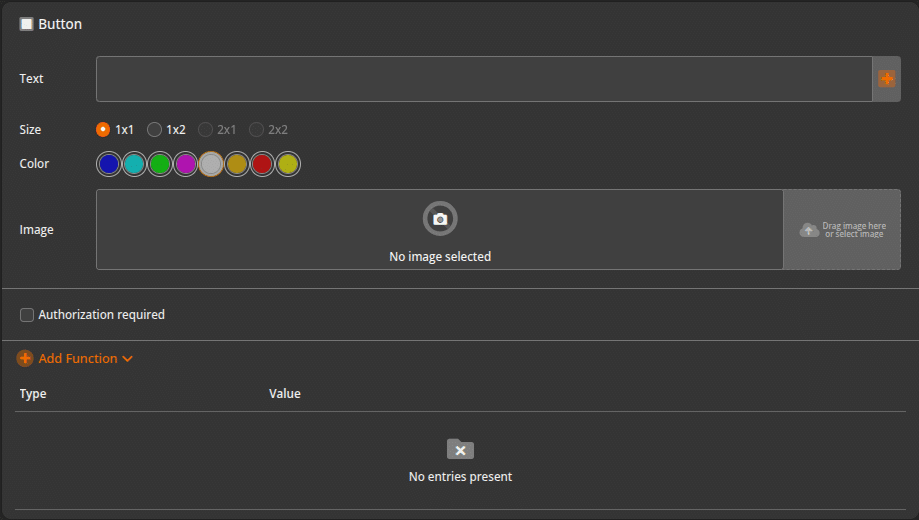

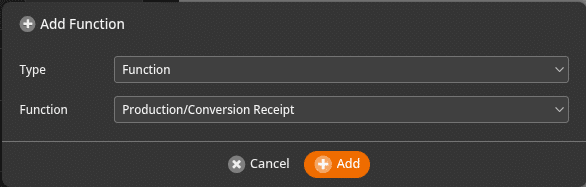

Select an empty button area and click on + Add Function to bring up the function dialog box. Select Type > Function and Function > Product/Conversion Receipt.

Start by ringing up your basket normally. Navigate to where you placed your Production/Conversion Receipt button. Select the Preparation Receipt Button.

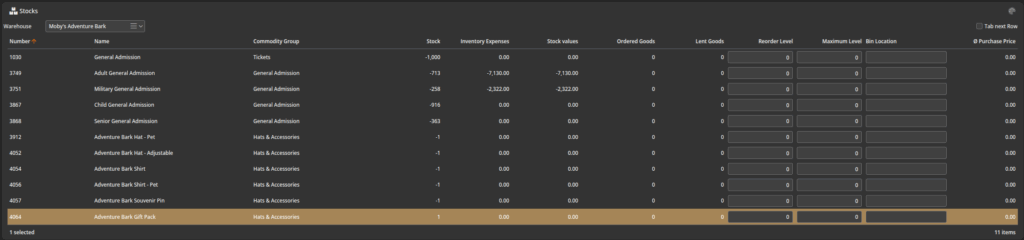

Your POS will produce a receipt that is labeled production. Looking at your stocks in the back office will reveal the result of this process. Notice how we now have one gift basket in our stocks. The inventory count of the items used in creating the basket has decreased by one.

Breaking up a product into individual items

You can also reverse the Production/Conversion process. For example, you had a multi-pack of an item set up and wanted to sell them individually.

First, you have the product that will be broken up into individual items. In this case, it’s the Magic Ring Case. This Magic Ring Case contains 10 rings. On the Magic Ring Case product, you tick on ‘Product Conversion’ and then add the Magic Ring as a sub-product with the amount that will come out of the case to be sold individually:

At your point of sale, enter -1, then ring up the case product. Navigate to where you placed your Product Conversion button. Select that Button.

Your point of sale will produce a production receipt, but it will indicate -1 by the product.

In your stocks, you will notice that the pack has gone down by 1, and the individual items used in the pack have gone up by 10. These will show in the stock history report as well for these products.

This is most common when you order cases of products but sell singles or smaller packs, such as beer. You can convert your cases -1 to generate appropriate quantities of Singles or smaller Pack amounts.

At your point of sale, enter -1, then ring up the product. Navigate to where you placed your Preparation Receipt button and click the Select Preparation Receipt Button.

Your point of sale will produce a production receipt as above, but it will indicate -1 by the product.

In your stocks, you will notice that the pack has gone down by one, and the individual items used in the pack have gone up by one.

Cost and Price

The cost of the basket is determined by the amount of the products added. Let’s say, for example, you create a gift basket, and your items come in at $25.00. That would also show up under the average purchase price in your stock’s view. You then create another basket at the cost of $30.00 in items. We now have spent about $55.00 making those baskets. Divide this by the number of baskets created. In this case, two baskets will yield an average price of $27.50.